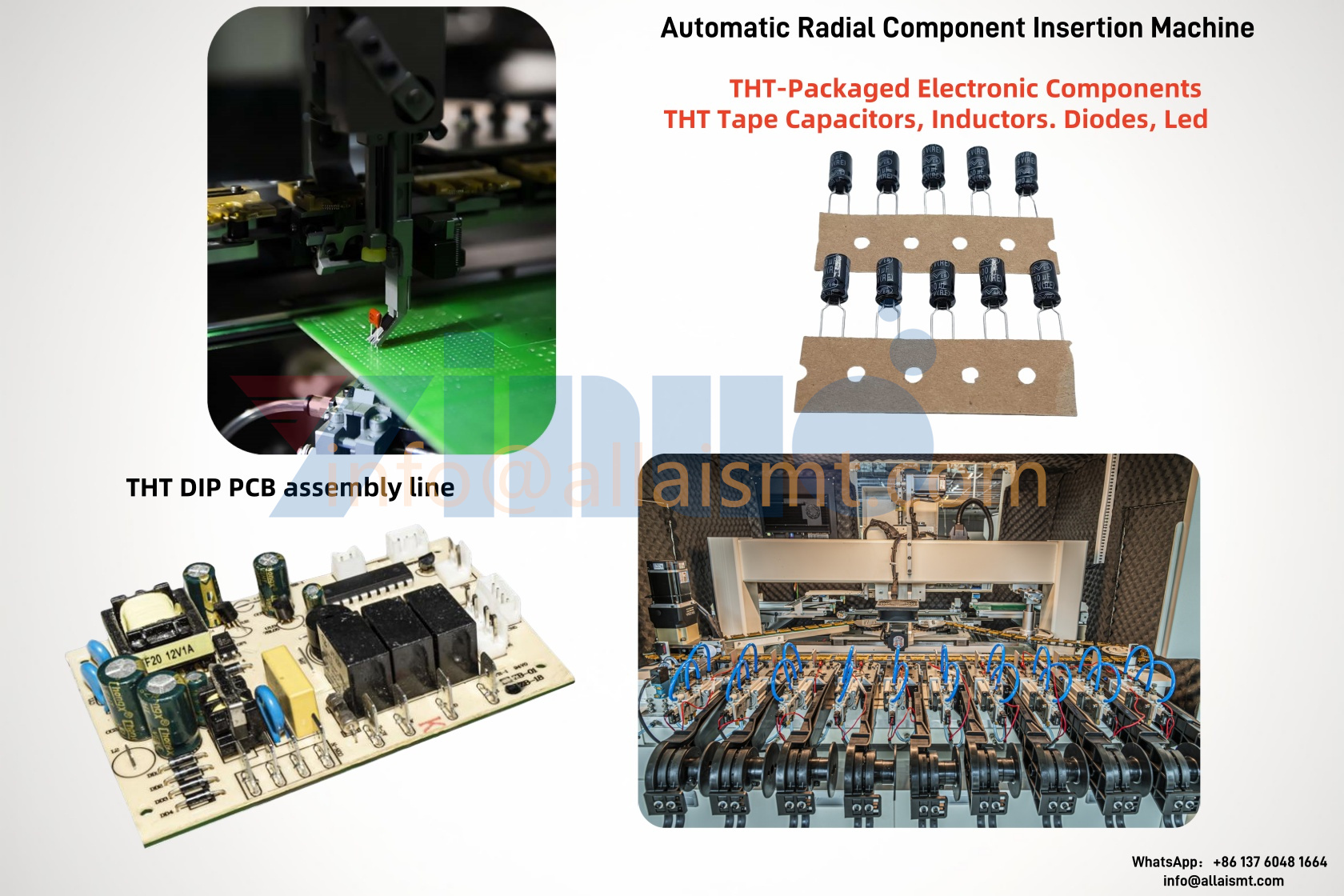

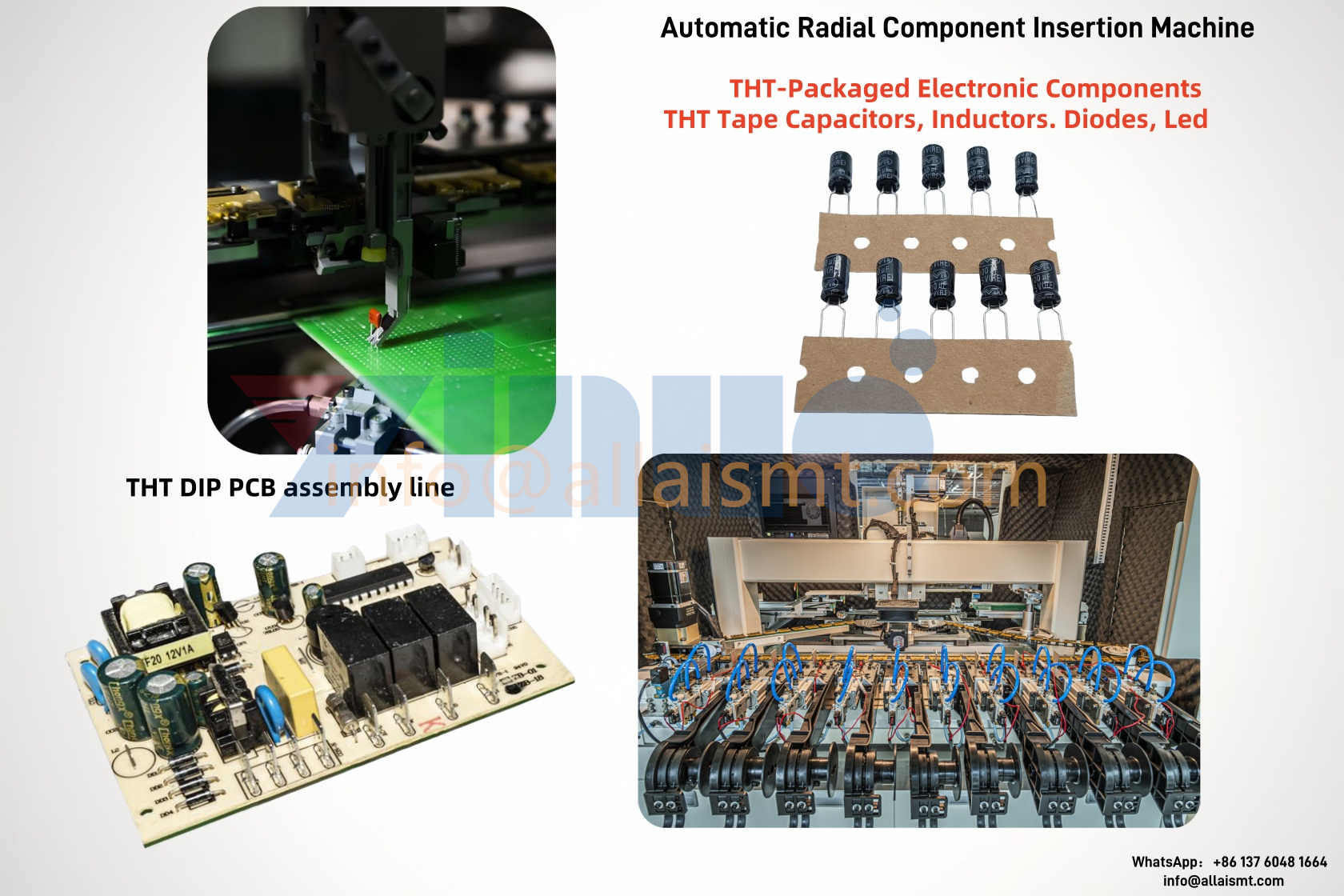

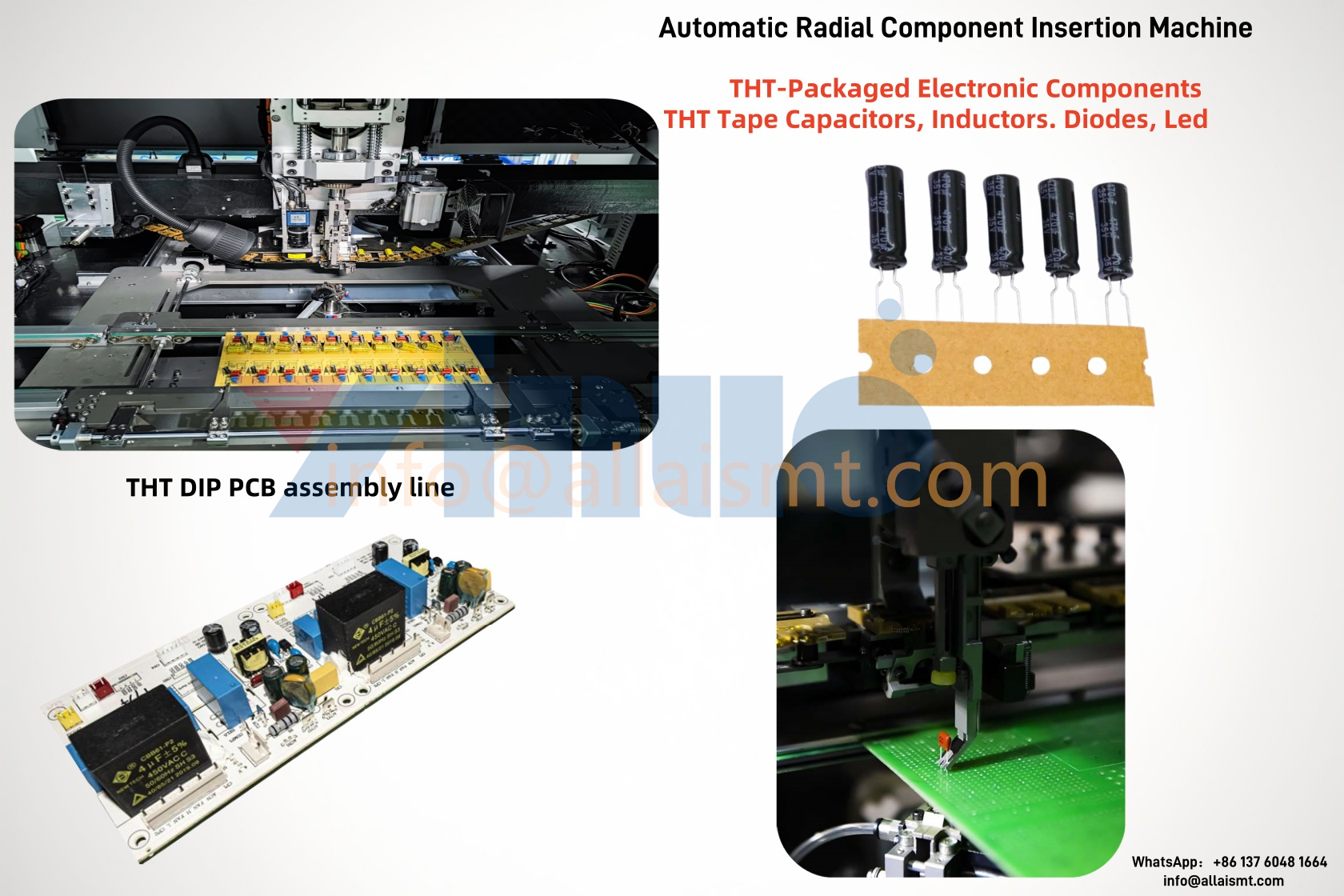

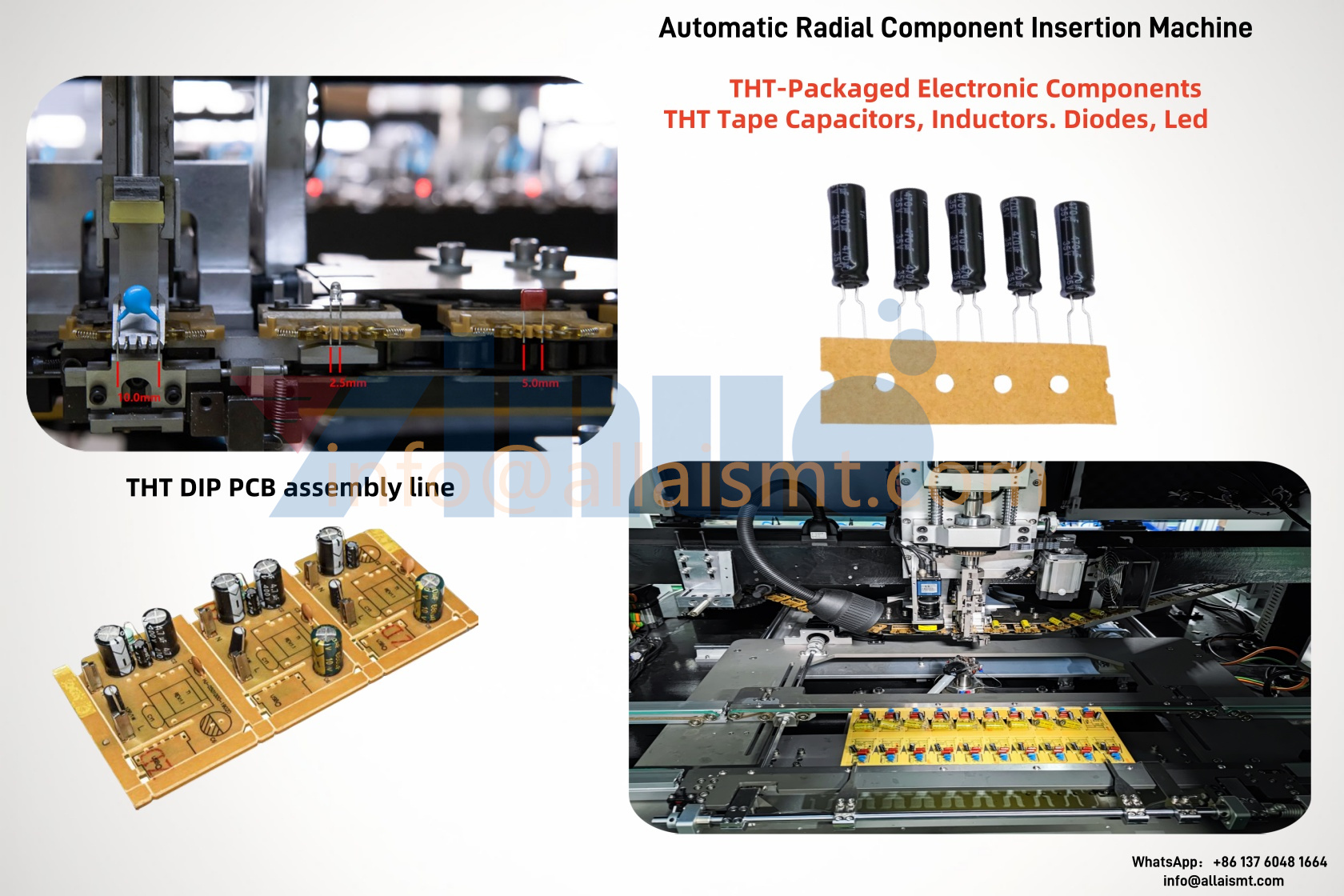

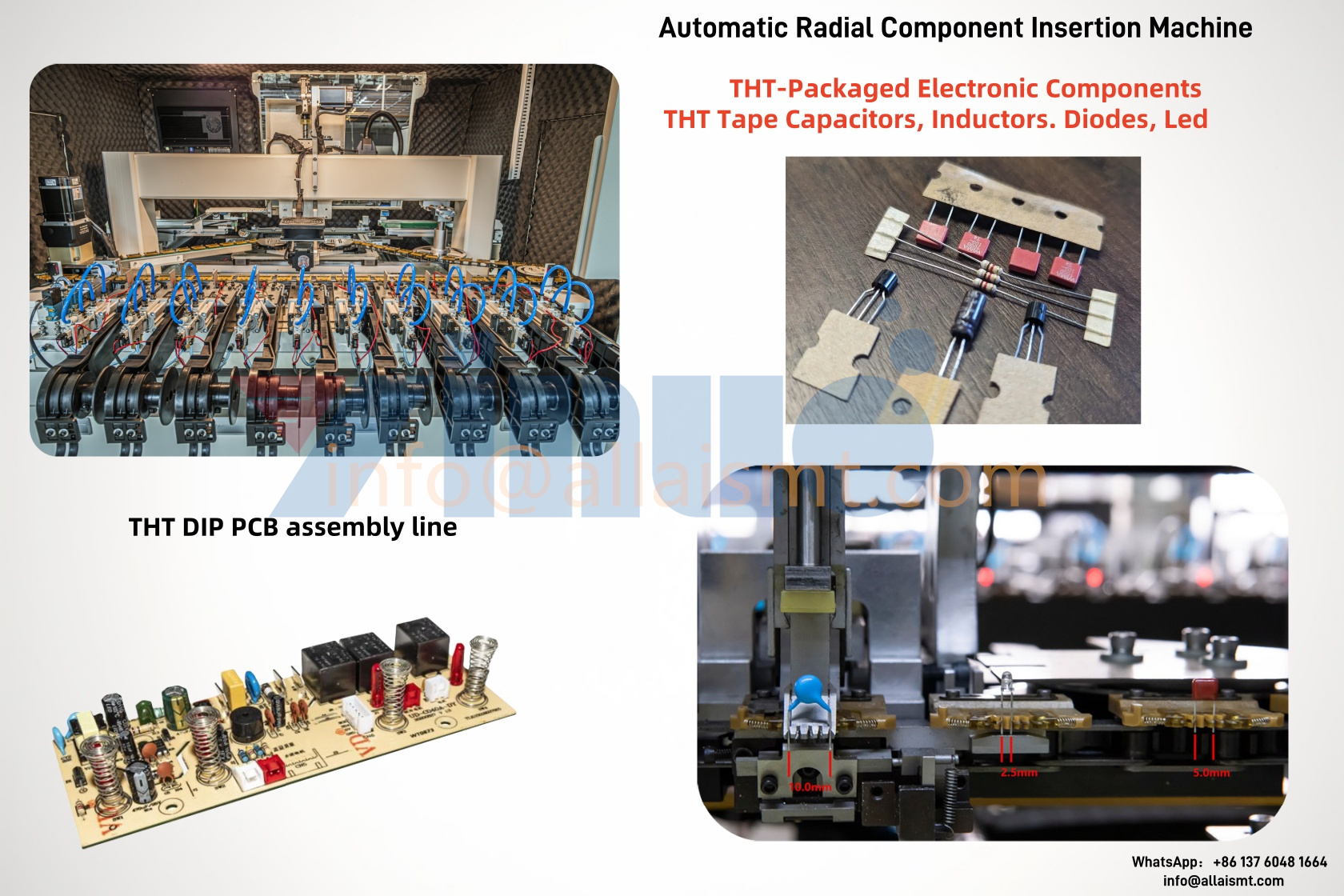

Automatic Radial Component Insertion Machine

### Introduction

In the ever-evolving field of electronics manufacturing, the need for automation has become more critical than ever. One such piece of equipment that has revolutionized the assembly process is the **Automatic Radial Component Insertion Machine**. This machine plays a vital role in the assembly of printed circuit boards (PCBs) by automating the insertion of radial components such as resistors, capacitors, diodes, and inductors into the board. The importance of this machine cannot be overstated, as it not only improves efficiency but also ensures high precision and quality in the final product.

### Key Features of the Automatic Radial Component Insertion Machine

1. **Component Loading and Handling**

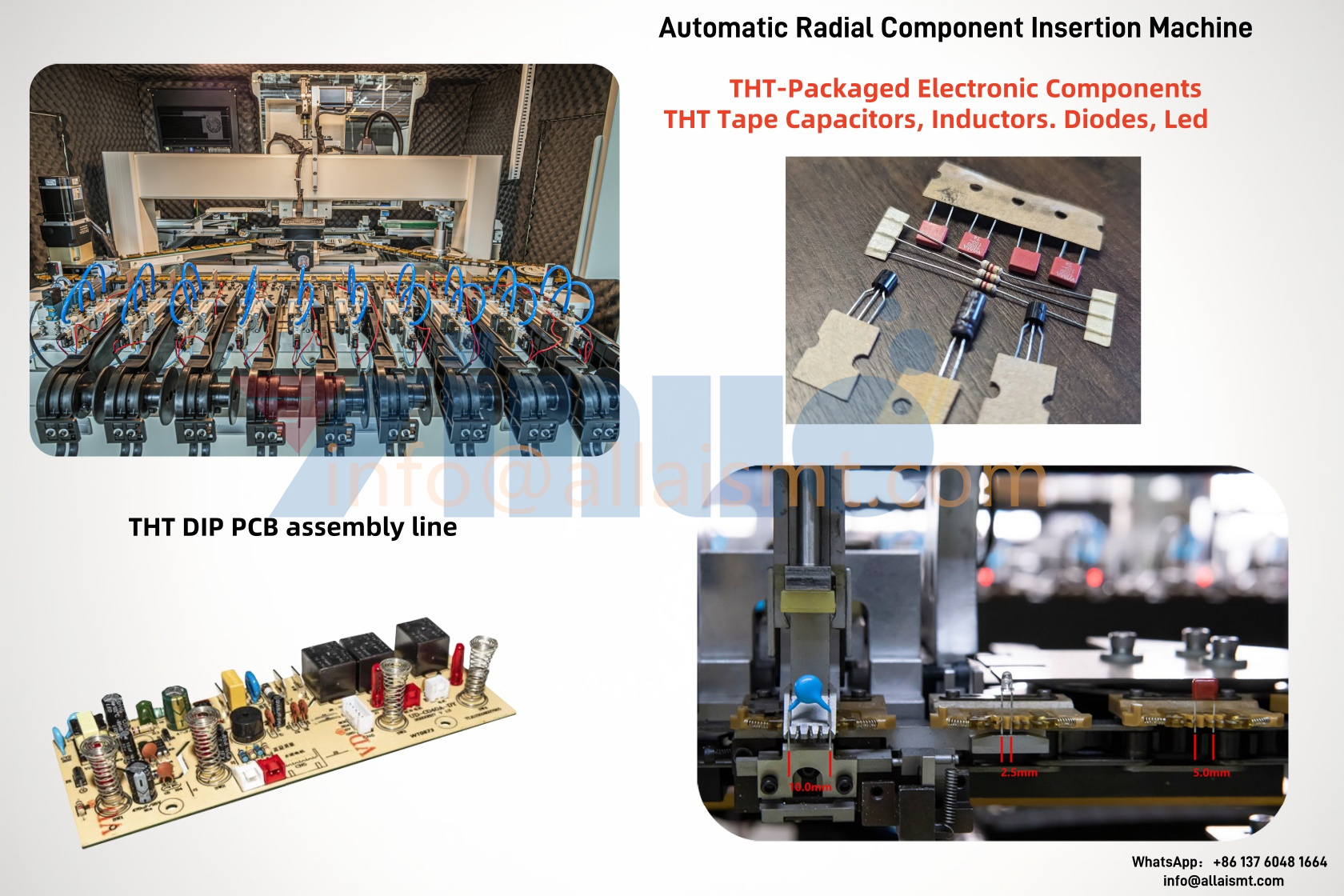

The automatic radial component insertion machine typically comes with component feeders or magazines that hold a wide array of radial components. These feeders are designed to automatically load components onto the machine for processing. This feature allows for continuous operation, minimizing downtime and reducing manual labor.

2. **Insertion and Securing of Components**

Once the components are placed over the PCB holes, the machine utilizes either pneumatic or electric actuators to insert the leads of the components through the PCB holes. After insertion, the leads are bent on the underside of the board to secure the components firmly in place. This process is essential for ensuring the components stay in position during subsequent soldering and assembly steps.

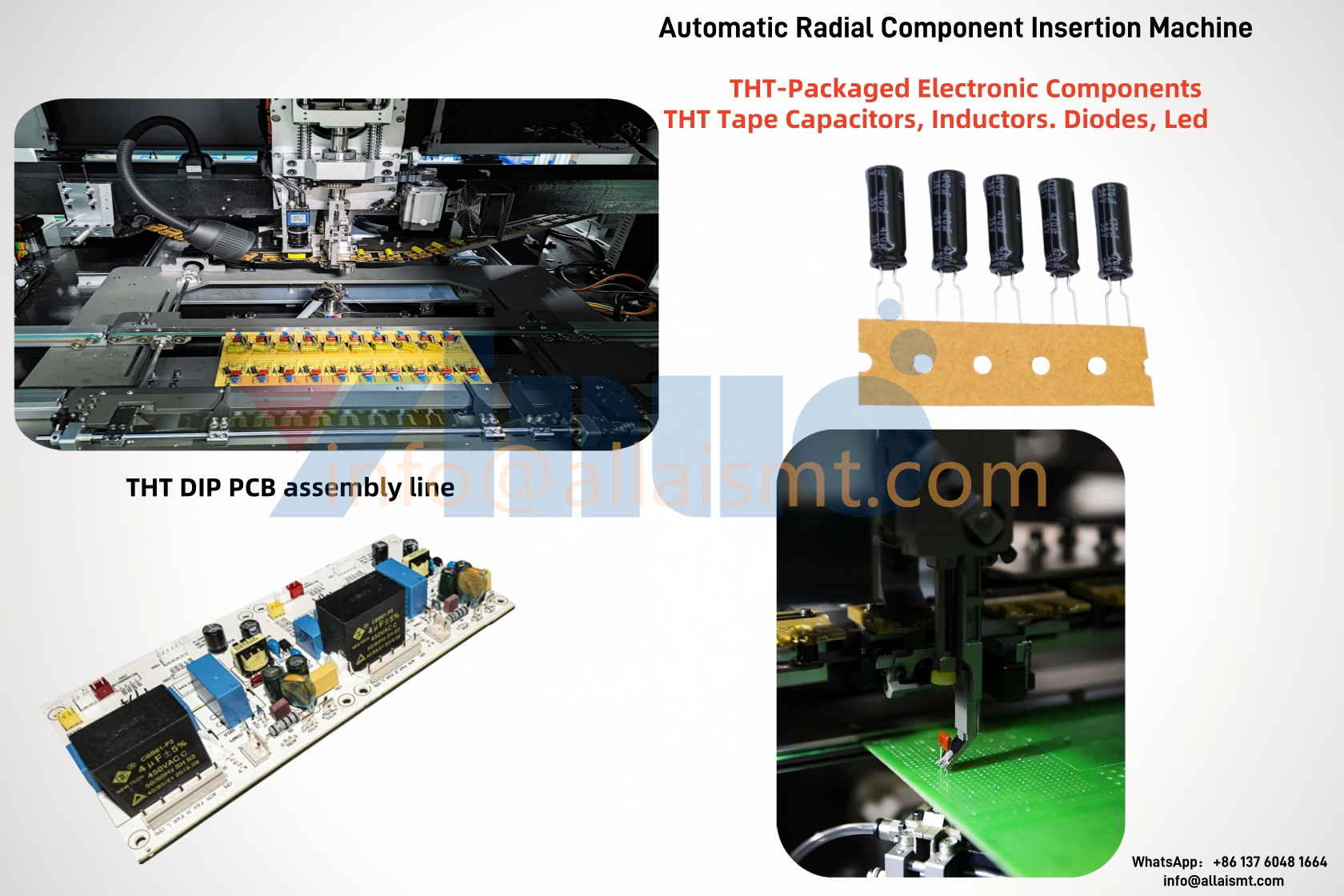

3. **Vision Systems for Alignment**

Modern automatic radial component insertion machines are equipped with **vision systems** that use cameras and sensors to detect the precise alignment of both the components and the PCB. The vision system ensures that the components are inserted at the correct angle and location, drastically reducing the risk of misalignment or faulty placements.

4. **Automation and Integration with Other Systems**

The automatic radial component insertion machine is often part of a larger automated production line, integrating seamlessly with other equipment such as **pick-and-place machines**, **wave soldering machines**, and **automated inspection stations**. This integration allows for a fully automated assembly process, reducing the need for manual intervention and ensuring consistency across the entire production line.

### Benefits of Automatic Radial Component Insertion

5. **Enhanced Speed and Efficiency**

The speed of the automatic insertion machine is a significant advantage in high-volume production. The machine can insert thousands of components into PCBs per hour, a task that would be highly labor-intensive and prone to error if done manually.

6. **Increased Precision and Quality**

The precision of automated insertion reduces the likelihood of component misplacement, incorrect orientation, or damaged leads. The machine’s vision system helps ensure each component is placed and inserted with perfect accuracy, contributing to higher-quality PCBs.

7. **Cost Reduction**

By automating the component insertion process, manufacturers can significantly reduce labor costs. The machine can operate continuously without the need for breaks, holidays, or shifts, making it more cost-effective in the long run. Additionally, fewer human workers are needed, which further lowers the overall labor expenses.

8 **Reduced Human Error**

One of the most significant advantages of automation is the reduction of human error. Manual component insertion is prone to mistakes, such as misalignment or incorrect placement. By eliminating the manual element, the insertion machine ensures that components are placed and secured with great accuracy, leading to fewer defective products.

9 **Scalability for High-Volume Production**

Automatic radial component insertion machines are designed for scalability, making them ideal for mass production. Whether a manufacturer is producing thousands of units or millions, the machine can handle large quantities of PCBs without sacrificing quality or speed.

### Industries Benefiting from Radial Component Insertion Machines

– **Consumer Electronics**: With an increasing demand for faster, more efficient assembly of electronic devices such as smartphones, laptops, and home appliances, automatic radial component insertion machines are indispensable.

– **Automotive Electronics**: Modern vehicles contain complex el

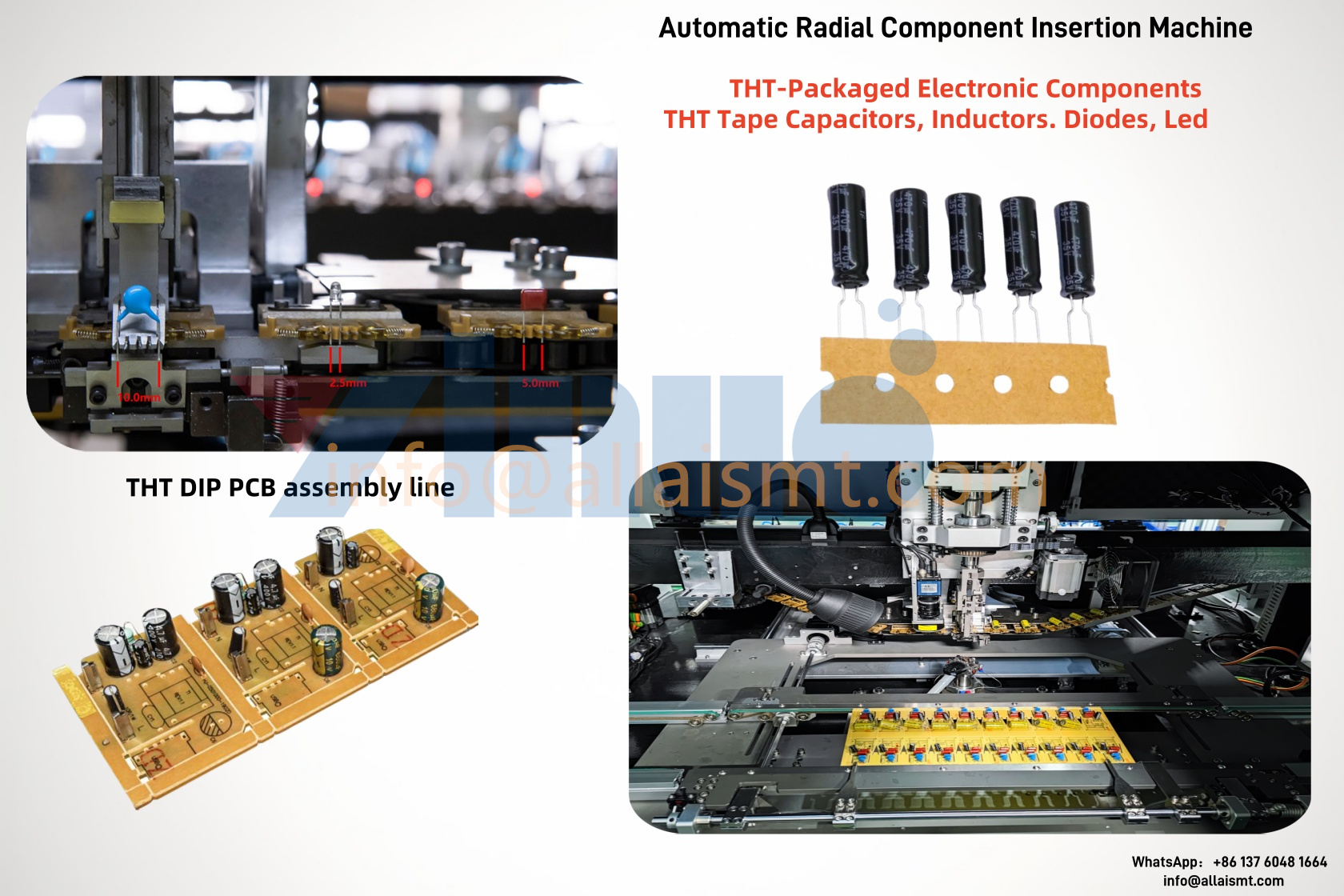

| Radial insertion machine (20 stations,online) |

| 1)2.5mm insert head |

| 2)The theory of speed:16000PCS/H |

| 3)Insert direction:0°-360°, 1°increasment |

| 4)servo motor drived insertion head(13.0mm)and clinch base “N” type. |

| 5)components require:standard tape packed radial leads components |

| 6)Components available:Capacitor, Transistor, LED lights, Key Switch, |

| Resistor, Connectors, Fuse Block and other vertical tape packed materials |

| 7)Core Machine Size (LxWxH)L2080xD1900xH1700 mm |

| 8)Core Machine Weight:1500KG |

| 9)Power supply:220V, AC (single phase) 50/60 HZ |

| 10)Air pressure: 0.6MPA, 0.3m3/minutes |

| 11)Circumstance temperature: 10° C. to 35° C. |

| 12)PCB transfer mode:Automatic , machine non stop. |

| 13)PCB Size:(Min)50 mm x50mm/Max)500mm x 300mm |

| 14)PCB thickness:0.79-2.36MM |

| 15)Clinch Length: 1.5-2.2mm(adjustable) |

| 16)Clinch degree: 10º-35º(adjustable) |

| 17)Coordinate correction:Machine vision systems. |

| 18)Non-Rotary table |

| 19)Machine vision caliberation systems |

| 20)Control System:English or Chinese version interface |

| 21)Yinuo Machinery platform software |

| 22)indutrial-control computer |

| 23)Adjustable fixture. |

| 24)12.7mm Dispensing head |

Automatic Radial Component Insertion Machine

Automatic Radial Component Insertion Machine

Automatic Radial Component Insertion Machine

Automatic Radial Component Insertion Machine

Automatic Radial Component Insertion Machine